Ironhead Top End Rebuild

Text and Pictures by Mark Trotta

Compared to the bottom end, rebuilding the top end of an Iron Sportster requires less time and less special tools.

The two main areas of concern are, if the cylinder jugs need boring, and if the valve seats need to be re-faced.

Read: Cylinder Head Removal

Read: Cylinder Head Cleaning and Inspection

If you're lucky, you may get away with just honing the cylinders, re-using the old pistons, and installing new piston rings.

DIY Rebuild Ironhead Top End

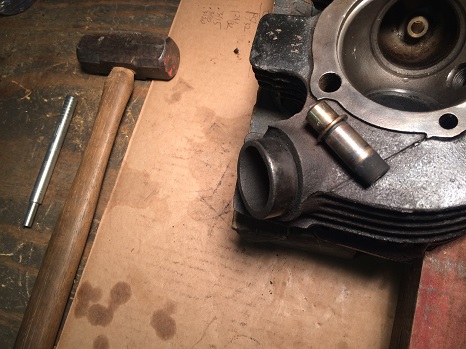

Aside from basic hand tools, you'll need a few motorcycle engine tools such as a piston ring installer and torque wrench. There are also a few specialty tools needed, although some of these can be fabricated.

Cylinder Boring And Honing

New cylinders, whether they are new or aftermarket, need to be accurately measured, bored, and honed. A good straight bore with a proper cross-hatch pattern, and correct piston to wall clearances, is a MUST for good sealing and ring life.

Read: DIY Motorcycle Cylinder Boring

Read: DIY Motorcycle Cylinder Honing

***********************

Ironhead Rebuild Kit

An alternative to measuring and boring your old cylinder jugs is to buy aftermarket ones. Rebuild Kits for 1973 through 1985 Ironhead Sportsters are still available.

Shop: Ironhead Cylinder And Piston Kit

The only physical difference between aftermarket Ironhead cylinders and factory cylinders is that they do not have casting numbers on them. Instead, they are marked "F" and "R".

***********************

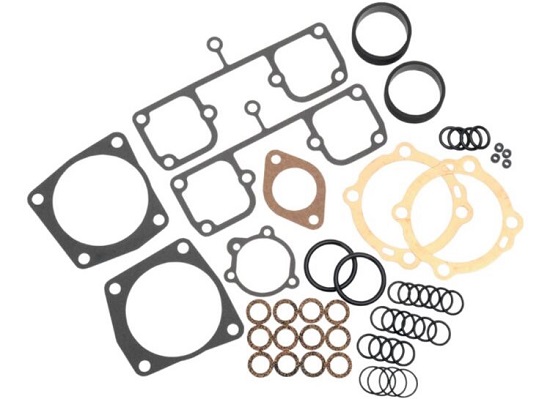

Top End Gasket Kit

James Gaskets are simply the best gaskets available for your Ironhead. Their top-end gasket kit replaces H-D 17030-72 and includes everything you need to re-seal your top end.

Shop: Ironhead Top End Gasket Set 1973-1985

This top end gasket set includes copper head-gaskets, oil seals, O-rings, and all other gaskets necessary to completely rebuild an 1973 through 1985 Ironhead top end. James Gaskets are proudly made in USA.

********************

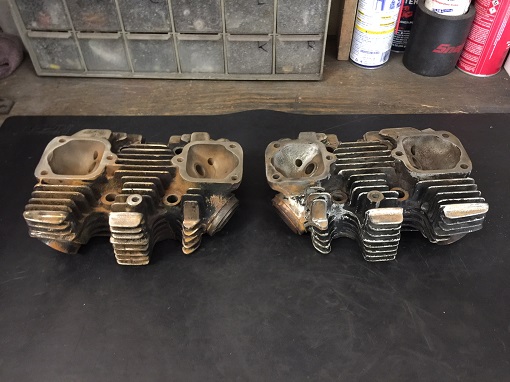

Cylinder Heads

Ironhead Sportsters are named after their cylinder heads. Since they're made from cast-iron, they're durable and rebuildable up to a point. The biggest problem often caused by the ham-fisted mechanic who tried fixing it before you.

Read: Ironhead Valve Job

Read: What Is A Three-Angle Valve Job ?

Read: How To Remove Valve Guides

Read: How To Install Valve Guides

Read: Ironhead Rocker Box Assembly

Read: How To Polish Aluminum Motorcycle Parts

********************

Related Articles:

Ironhead Engine Build

Cylinder Head Removal

Repair Cracked Cooling Fins

Ironhead Sportster Cylinders

Rocker Box Assembly

Remove/Install Sportster Cam Bushings

Install Sportster Cams

How To Adjust Ironhead Valves