Motorcycle Cylinder Boring

article by Mark Trotta

If you want optimum performance and life from your motorcycle engine, cylinder bores need to perfectly round. This means uniformly round at the top, middle, and bottom. Most manufacturers specify this tolerance to be .002" to .003".

How Cylinders Wear

A piston has two sides, a thrust side and a relief side. During a four-stroke engine's operation, pistons get pushed down on the stroke cycle. This puts force on the front of the cylinder wall, which is the thrust side. Over time, this creates an oblong, or "out-of-round" shape in the cylinder.

To rebuild an engine to correct factory specs, a worn cylinder gets bored out, until it's perfectly round again, to the next oversize piston size.

DIY vs Machine Shop

If you're rebuilding an old motorcycle engine, boring a cylinder back to round requires removing anywhere from .003" to .010" or more of metal. Professional machine shops have large, expensive, dedicated machines to perform all kinds of cylinder boring. When operated by an experienced user, these machines are quick and accurate.

The same process can be done in your home garage, but will take considerably more time. By using a rigid honing tool and a slow-speed drill, DIY cylinder re-sizing is possible.

Cylinder Honing vs Cylinder Boring

Many people use the words "bore" and "hone" interchangeably. Boring is a process that is done with expensive machine shop equipment, where as honing can be done in a home garage. The difference is how the metal is removed.

A cylinder boring machine has a fixed vertical arm which slowly spirals down into the bore, cutting the cylinder walls like a big drill. Honing, on the other hand, is removing metal by friction, somewhat like sanding down metal with a piece of sandpaper.

For the home machinist, honing is done with a hand-held drill and rigid honing tool. For fastest results, dry, coarse stones (100 grit) are used.

After the honing process is completed, the cylinder walls need to be "finished" to help the new piston rings to seat correctly. This second process to cylinder honing can be done with the same tool using finer grit stones, or a flex hone tool. Either medium (220 grit) or fine (320 grit) stones are used for finish-honing.

Rigid honing removes metal, whereas flex-honing only "dresses" metal.

Read: Motorcycle Cylinder Honing

Disadvantages Of A Rigid Honing Tool

A hand-held rigid honing tool can only follow the current shape of the cylinder, so if the bore is "crooked" or not perpendicular to the crankshaft, it generally stays that way even though you bored it to a larger size.

******************

Tools Needed To Bore Cylinders

First, we need to understand the difference between a surface finishing tool, like a ball-type hone or a three-stone hone, and a material removal tool, like a rack-style rigid honing device. You can't bore a cylinder with a surface finishing tool. Technically, you can, but it would take a long, long time.

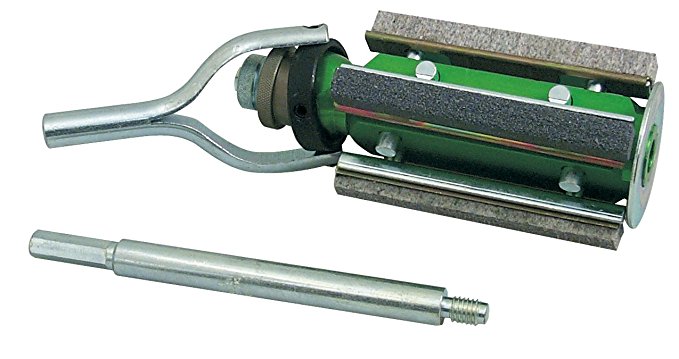

Hand-held rigid honing tools can be used to bore all types of small engine bores. The tool I use is a Lisle 15000 which services 3" to 4-1/4" cylinders. It is a rack-style and has two stones and two wipers which clip on and off. There is a universal-joint between the handle and the head. After hooking it up to a 1/2" drill, press the trigger and the tool starts rotating, which expands the tool head to the cylinder size.

Cylinder Boring Procedure

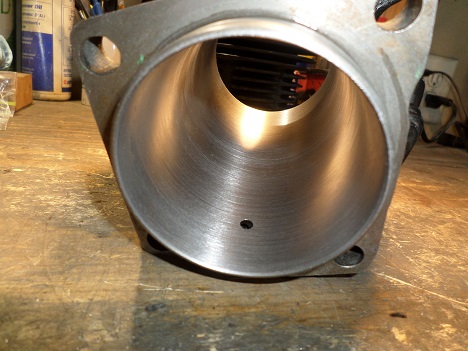

In a sturdy-mounted bench vise, set the cylinder up horizontally. Stroke quickly but at a slow RPM. The rule of thumb is 100 RPM for every inch of diameter bored. For example: 300 RPM is ideal for a 3" bore, 200 RPM for a 2" bore, etc.

For the quickest results, boring is done dry, meaning, no lubrication is used. This provides the fastest metal removal, but may overheat the metal. Let the metal cool between boring and measuring.

Adding oil will increase the life of the stones and helps keep the heat down, but makes the cutting process slower. Remember that once wet, honing stones cannot be used dry again.

Stop and Re-Measure Often

Keep the hone moving in and out slowly. If there's any deep scratches and grooves, you'll need to take them out gradually. Do not stop in one place for too long--stop and remeasure often. Reverse the cylinder in the vice several times during the process.

Remember, you don't want to take off too much metal, nor do you want to take off too much metal in one spot. Stop and measure often. Remember to reverse the cylinder in the vice several times.

Most service manuals call for .002"-.003" tolerance across the bore. I aim for .003" at a minimum, then concentrate on a good hone.

With 100-grit stones you can usually take .010" out of a small engine cylinder in about 30 minutes. Remember that you're not removing the entire .010" by boring alone, you need to leave a small stock allowance for honing, usually 0.002" to 0.003". If you were boring .020" or more (a bit of a workout by hand) you would still leave the 0.002" to 0.003" for final finishing.

Lisle 15000 Honing Tool

I've found the Lisle 15000 honing tool to be versatile and competitively priced. Included with the tool is a storage case, cleaning brush, and a set of 100 grit (#15500) coarse stones and 320 grit (#15510) medium stones.

Additional honing stones for the Lisle 15000 are available in five grits to cover different cylinder's materials. They also offer additional rack sets, to adjust hone range for larger or smaller bore sizes.

Boring a cylinder by hand will certainly take longer than paying a machine shop to do it, but the results can be just as accurate. Remember that even with the best equipment available, an uncaring or incompetent operator can easily screw up.

With the right procedures and correct measurements, excellent results can accomplished with a hand-held rigid honing tool.

******************

Cylinder Finish Honing

After a cylinder is honed or bored to size, the cylinder walls need to be finish-honed for new piston rings to seal properly. Similar to boring machines, machine shops have a special honing machine that does the job fast and easy.

For best results, cross hatch with a quality flex hone on an electric drill.

Read: DIY Motorcycle Cylinder Honing

Honing cylinders is needed to promote easy break-in of new piston rings. The honing process is much easier and much less time-consuming than the boring process. You're only removing the last .0015" or so with 320 grit stones.

Clean and Oil Cylinder Walls After Boring/Honing

When you're through boring and honing, clean the cylinder walls. One way is too wash with hot soapy water, then dry with compressed air. Another way is to wipe the walls with ATF fluid on a clean white cloth (like an old T-shirt).

When they're dry, apply a light coating of oil (10W30, ATF, etc) to the bores. This is to prevent rusting.

If you're not assembling the motor for a few weeks, put oiled cylinders in a plastic bag and out of the way until needed.

******************

When Not To Bore A Cylinder Yourself

If you have a rare, antique, or hard to replace cylinder, consider sending it a reputable shop that specializes in vintage motorcycle repair.

If your cylinder is way out of round, deeply scratched or scored, or needs .030" or more removed to make it round again, consider having it sleeved and then line-bored.

******************

Measure Piston To Cylinder Clearance

Optimum piston-to-bore clearance is usually .004 to .005 inches, but varies slightly depending on the manufacturer. To measure piston to bore clearance, place the piston into the cylinder. A feeler gauge can be used to measure clearance between the piston and cylinder wall. Piston measurement is taken from the bottom of the skirt.

Start with a relatively small (.001") feeler gauge strip, and gradually increase the size until the piston will barely slide in. Double this measurement (per side) and that will give you your running clearance.

******************

Measuring Cylinder Wear

Dial Bore Gauge

Cylinder bore wear needs to be measured in six places: top, middle, bottom (front to back), and top, middle, bottom (side to side). Since the rings don't travel to the top of the bore, do not include the top 1/2" of the cylinder while measuring.

To accurately measure the inside diameter of a cylinder, a dial bore gauge is needed. The tool I have is a ToolUSA TM-34260. Bore range goes from two to six inches. It has a bore depth of six inches, and the dial has .001" increments.

Shop: Dial Bore Gauge

Keep in mind that .005" too tight can seize a piston when warmed up, and .005" too loose and you'll get noisy operation (piston slap). But, better too loose than too tight - a bit of rattle is much better than a locked-up motor!

For full article on Measurement Tools For Engine Builders click here.

******************

Are Torque Plates Necessary?

Torque plates simulate the stresses that are encountered when cylinders are torqued onto the engine cases. Like line-boring, all race and performance motors require torque plates when cylinder boring. Torque plates can either be bought or fabricated.

All aluminum cylinders will require torque plates during the boring process. Vintage motorcycle cylinders with cast-iron sleeves (liners) inside an aluminum cylinder should use them as well. For a street-driven bike with cast iron cylinders, torque plates aren't necessary.

******************

A Word About Two-Stroke Engines

If you have a two-stroke engine, boring/honing a cylinder is more difficult because of the missing material on the sides (transfer ports). These port holes may cause the hone to cut oversize below the ports on the sides.

******************

Related Articles: