Measurement Tools For Engine Builders

Article by Mark Trotta

Quality engine rebuilding starts with quality measuring instruments. These include micrometers, calipers, dial indicators, dial bore gauges, small hole gauges, and of course, feeler gauges.

******************

Types Of Calipers

Micrometer calipers, often called micrometers, have many uses. They can measure length and width, as well as inside diameter or outside diameter of an object.

Measuring bushing I.D. with secondary jaws

Most operate on a rack and pinion, and feature two sets of jaws for reading both external and internal measurements. They can also read step measurements and depth measurements.

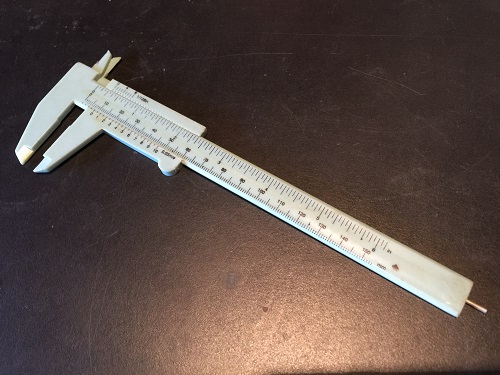

My collection of measurement instruments started with a cheap plastic Vernier caliper. They work on a rack and pinion and require no power source.

My present one is a digital Mitutoyo which has seen 10 years of service so far.

Digital calipers are more expensive than vernier or dial calipers, but they are easier to use and quicker to read.

While rebuilding the bottom end of an early Ironhead Sportster, I could not assume that all 51 new roller bearings were exactly the same size. I checked the diameter of each and every one before installing.

For complete article on Digital Caliper For Engine Building click here.

******************

Outside Micrometers

Common uses for outside micrometers include measuring crank journals and connecting rod journals. Along with a dial bore gauge, they can accurately measure cylinder bore diameter.

Because of their super-precision, outside mics are offered in one-inch increments; 0-1", 1-2", 2-3", etc. They are also available in metric as well; 0-25mm, 25-50mm, 50-75mm, etc.

The most common outside micrometer size for engine building is one with a 0-1" Measuring Range.

Also common is one with a 1-2" Measuring Range.

******************

Mag Base DTI

A Dial Test Indicator (DTI) allows for measurements in tight spaces. During an engine build, they are needed to check clearances, and are usually mounted on a rod or magnetic base stand.

DTI With Magnetic Base

Having a dial test indicator allows you to check end play, flywheel run-out, up-and-down movement on connecting rods, and many others. Most have increments of .001" on a 0" to 1" scale. They can be mounted by clamp or magnetic base.

In the picture above, I'm checking thrust clearance on a Harley 45 Flathead with magnetic-base dial indicator.

Flywheel Truing

A magnetic base dial indicator allows many options as to where it can be mounted.

On my homemade flywheel truing stand, I have a DTI on either side, which makes measuring easier. You could get by with just one, but you'll be moving it from side to side to get left and right readings.

******************

Bore Gauge

To accurately measure the inside diameter of a cylinder, a dial indicator bore gauge is needed.

Most will have a range of two to six inches, a depth of six inches, with a round dial of .001" increments.

Here I'm checking the bore diameter of an Ironhead Sportster cylinder.

******************

Small Hole Gauge

To accurately measure the inside diameter of valve guides (and other small bores), a small telescoping gauge is required.

These are also called small-bore gauges, and come in varying sizes.

How they function is, the gauge expands in the bore, and the user then locks it in place. Once removed, it gets measured with an outside micrometer or digital caliper to determine final hole size.

To check valve guide clearances - Once the guide I.D. (inside diameter) is obtained, measure the O.D. (outside diameter) of the valve stem. Subtract that figure from the I.D. of the guide and that's your clearance.

Read: How To Measure Valve Guide Wear

******************

Feeler Gauge

A feeler gauge, or gap gauge, is needed for checking valve tolerances, ignition point gaps and other critical measurements. They're made up of thin metal blades. Each blade is a different width of precise thickness, and will be marked in either thousandths of an inch, or millimeters, or both.

Measuring valve lash on a Kawasaki XZ650

The blades usually range from .0015" to .035" (.038 to .889mm) in width. And if needed, you can also pair two blades together.

Long feeler gauges may be required for valve adjustments on some engines.

******************

Steel Rule

A six-inch steel rule comes in handy when quick fractional measurements are needed.

One of it's many uses on a motorcycle is measuring primary chain wear.

It's also helpful for determining lengths of bolts, cotter pins, washer O.D. etc.

******************

Double Checking/Practice Measuring

Engine clearances are critical, not only for maximum performance, but also for long, trouble-free service. Learning to correctly read precision instruments takes practice. First-time builders should measure a dozen times (or more) before trusting their readings.

Machinists who have years of experience still double-check their specs.

Remember that micrometers, dial indicators, and dial bore gauges are precision measurements, and need to be treated as such. For consistent and reliable results, keep them clean and out of harm's way.

******************

Fun Fact: Micrometers are used in microscopes to measure the diameter of microscopic objects. They are also used in telescopes to measure the apparent diameter of celestial bodies.

******************

Related Articles: