Motorcycle Cylinder Honing

text and pictures by Mark Trotta

After engine cylinders are bored to size, cylinder walls need to be finish-honed for the new piston rings to seal properly and have a long life. Similar to a stationary boring machine, machine shops have a special honing machine that does the job fast and easy.

For the DIYer, this is often done by cross hatching with a quality flex hone and an electric drill.

This article covers the two most popular tools for finishing motorcycle cylinders--flat stones and flex hones.

Flat Stone Hones

A 3-stone hone like the one pictured below is commonly referred to as a glaze breaker. It is usually operated with a hand-held drill.

Many flat stone hones have three 220-grit stones on a flexible shaft. Operation is done by a hand drill on slow speed of approximately 150 rpm. The advantage over flex hones is they're cheaper, and they're also adjustable, so the same tool can be used on several different sized bores.

Flex Hones

Ball honing, also known as flex honing, is done with a Flex Hone Tool which has dozens of small flexible balls. It is also commonly operated with a hand-held drill.

If the bores are good, meaning there's no ridge or scoring, a flex hone will quickly produce a professional-looking finish without taking any metal off.

Pictured: ball/berry type hone.

Aside from cross-hatching, flex hones can also be used to deglaze a cylinder.

********************

Stone Hone vs Flex Hone

If your cylinder has just been bored by a machine shop, it's probably OK to use a stone hone. But if you're re-using an existing bore, flex honing is the preferred method for de-glazing. Here's why: as a cylinder wears, there are slight irregularities up and down the bore that flat stones just can't get.

Because it's not flexible, a stone hone tool will not correct any deviations in the cylinder wall. On the other hand, flex-hones are self-centering, self-aligning, and compensate for cylinder wear.

********************

Flex Hone Operation

Some people prefer a drill press, but personally, I feel more in control with a hand-held drill.

Instead of honing at full drill speed moving slowly back and forth, work at slow speed with a vigorous movement back and forth.

Tip: For a perfect cross hatching, have your drill spinning at low speed before you slide the hone tool in. This will give it the best 45° cross hatching.

Quick In And Out

- Hold the drill and flex hone above or outside the cylinder

- Start the tool slowly spinning outside the bore

- Plunge straight down and exit the bottom of the bore.

- Pull straight up and exit the top of the bore.

- Do not stop with the tool in the bore.

Standing and bending over a cylinder is awkward, but it gives the best position for the up and down action. Alternately, you can mount the cylinder horizontally in a workbench vice.

Repeat the process no more than necessary (usually 8-10 times) until you get the pattern you want.

Clean and Oil Cylinder Walls After Honing

Whichever method you use, when you are through honing, clean the cylinders thoroughly with hot soapy water, then dry with compressed air. After they're completely dry, apply a light coating of oil (10W30, ATF, etc). This will prevent the bores from rusting.

If you're not installing them for a few days or a few weeks, place the oiled cylinders in a plastic bag and out of the way until needed.

What Is The Best Flex Hone?

Brush Research Manufacturing (BRM) introduced their flex-hone tool in 1972. If you're looking for the best way to hone a motorcycle cylinder, these are the answer. Unlike flat stone hones, they are self-centering, self-aligning, and compensate for cylinder wear.

All Brush Research flex hones are made in the USA.

If you're installing new rings a 320 hone from Brush Research does a great job at deglazing while leaving a nice crosshatch.

Remember, to get a proper crosshatch pattern, the key is to work at a slow speed but with quick back and forth strokes.

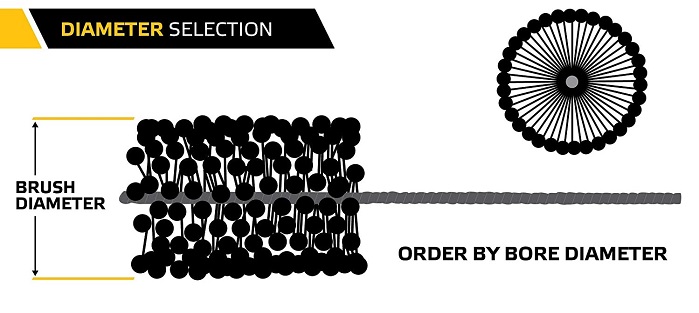

Order By Bore Diameter

A flex hone's diameter should be slightly wider than the bore diameter you're using it in. So, order the tool for the bore size you need. For example, you need a 3" flex-hone for a 3" bore.

********************

Misc Notes

If the exact size is not offered, round up to the closest available size.

If you try to stuff an oversized ball hone into a bore, you can wreck the hone.

Bore vs Hone

Many people use the words "bore" and "hone" interchangeably. Technically speaking, cylinder boring is a process that is done with machine shop equipment. When performed in a home garage using hand-held equipment, it's actually honing. It will produce the same results, it just takes a lot longer with hand-held equipment.

Two Types Of Cylinder Honing

There are two distinct types of cylinder honing processes.

The first is, as stated above, when you are increasing a bore size to the next oversize with a hand-held rigid hone. This is called rigid-honing.

The second process, commonly called finish-honing, is achieved by using either a stone hone or a ball hone.

Rigid-honing removes metal, and finish-honing "dresses" metal.

Why Do I need To Finish-Hone Cylinders?

Without proper honing, new piston rings cannot do their job correctly, which results in lost compression and high oil consumption.

A cylinder needs to be finish-honed for one of two reasons. If you are re-using your old pistons but installing new rings, you may notice the cylinder walls have a shiny finish. This happens by a piston's constant up and down motion, which eventually "polishes" the cylinder walls. Too smooth a finish prevents new piston rings from properly seating with the cylinder bore. So if you're re-using a good used cylinder bore, you want to break the glaze and leave a nice cross-hatch pattern.

The second reason to hone a cylinder is when it has just been refinished to a different bore size. For either of these reasons, you need to provide just a slight amount of roughness for oil to cling onto. The tiny peaks left behind by either honing process provides just enough roughness to allow the rings and cylinders wall to wear together.

********************

Two-Stroke Engine Honing

A bonus when flex-honing two-cycle engine cylinders is, they'll put a slight chamfer on the edge of the ports for you. This eliminates the extra step of radiusing the edge.

Caution: When honing a two-cycle cylinder, the flex hone must be within 1/8" of your bore size, or the stones may catch on the ports and cause damage.

******************

Related Articles: