How To Remove Valve Guides

Article by Vintage Vinny

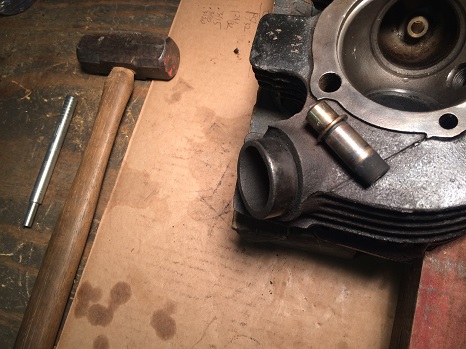

Overhauling cylinder heads often includes valve guide replacement. Once the head is off the motor and valves are removed, the guides and valves can be checked and measured for wear.

A general rule of thumb is .002" play is OK before replacement is needed. Check with the factory service manual for specs on your exact year and model.

Exhaust guides always need a little bit more clearance. This is because they run hotter than the intake side.

Before removing, clean any carbon off the outside of the old guide. Guides generally get driven out from the bottom, underside of the head. Some valve guides have shoulders or collars, so there is only direction they will come out.

Valve Guide Removal

Worn guides are generally pressed out with new ones pressed back in. There are several ways to do this; they can be pressed out on a shop press, air-hammered out, or driven out with a hand-held hammer.

A shop press would work quick and easy if your guides were straight up and down with the cylinder head sitting flat. But since this is usually not the case, a jig of some sort would be fabricated to prop the head up at the correct angle.

An air hammer is an awesome tool; it can deliver 3,500 small and steady blows in a minute. Although using an air hammer would remove guides quicker, you get a better feel for the tightness of the guide by using a hand-held hammer.

A long-handled 2.5 pound sledge hammer works well for driving valve guides in and out of iron cylinder heads.

Valve Guide Drivers

There are different size drivers for different size valve guides. One end has a smaller diameter "step-down" that slides into the I.D. of the guide. This not only prevents guide distortion, it also helps to stabilize the driver when being used.

If you're working on a pre-Evo Harley, three guide drivers (5/16", 11/32", 3/8") will cover you.

Shop: Valve Guide Driver Set

Prop the head on your workbench in a way that it won't move when you smack the driver with the hammer. Wearing safety glasses is recommended.

Cast iron cylinder heads do not need to be heated up for valve guide removal. Aluminum heads need to be heated up slightly. A propane torch works nice for this.

With the right-size hammer, guides usually come out in 10 to 20 strong, steady swings. If any of the guides were looser than the others, make a note of it. If a guide is "stubborn" and does not move after 15 or 20 smacks, try an air hammer.

With the old guides removed, measure the I.D. of the guide hole in the head. The best way to measure is to use a snap gauge and dial bore gauge or micrometer.

Allowable guide to head tolerance is generally .0015" to .002". Any looser than that, look for an oversize O.D. guide. New guides are commonly offered in .001" and .002" oversizes.

Valve Guide Replacement Alternatives

If you do not have access to the necessary tools or to a machine shop, there are several alternatives to removing and installing valve guides. Buying oversized valves is one option. Choosing this method would involve precise measuring, then slow and careful drilling of the old guide. It then needs to be finished with a reamer for final fitment.

The downside of oversize valves is that they are more expensive then standard size valves, and may not be offered in the size you need.

Knurling Valve Guides

A knurling tool is spiraled, somewhat like a bolt. When the tool is run through an old guide, it displaces the metal and makes the diameter of the hole smaller. The rolling method of knurling does not remove metal, but rather raises it up in rings. The guide then gets reamed to the proper size.

For those on a budget it is certainly an option, but there is a limit as to how loose a guide can be to be safely knurled. For engines with cast-in guides, knurling may be the most practical way to do a lower-cost valve job.

Some will argue that the rings left by knurling process hold extra oil, which increases lubrication over non-knurled guides. But a knurled surface will always wear quicker than a new guide because of the missing surface area.

It's hard to say how many miles knurled guides will last before the engine starts burning a little oil and blowing out blue smoke. Perhaps 10k, maybe 20k miles, but for an old motorcycle that doesn't get driven regularly, knurling valve guides is always an option.

******************

Related Articles: