Remove and Install Norton Commando Isolastics

It's because they're not easily accessible, that's why replacing Norton Isolastics is such a time-consuming job.

But once you get to them, if the tubes are clean and parts properly lubricated, they will install easily.

Front Isolastics Removal With Engine Still In Frame

You'll need to raise the front of the motor to take pressure off the ISO mounting. One way to do this is with a small bottle jack under the engine. Stock exhaust may need to be removed.

Unfasten the long through-bolt (front engine mounting bolt). If it does not pull out easily, tap it through with a drift and hammer.

Sliding out the bolt releases the gaiters, collars, washers, caps, and shims.

The inside rubbers can be pulled out by inserting a large screwdriver and twisting up and down.

Clean Out Tube

The inside of the ISO tube needs to be clean and clear, or you will have trouble installing the new parts.

After wiping clean (brake parts cleaner and shop towels work well), run a drill-mounted wire brush and/or drill-mounted cylinder hone through the bore.

Pictured: flexible cylinder hone tool with 220 grit stones.

***************

Front Isolastics Removal With Engine Out Of Frame

On this 1974 Roadster, the motor was removed with front mounting still attached.

Related article: Norton Commando Engine Removal

After years of sitting, the engine's weight distorts the rubber bushings.

If the metal sleeve is no longer in the center, it's time to replace!

***************

Three Types of Front Isolastics

1) The original version with shims.

On MK1 and MK2 models, original Isolastics were multiple pieces with shims, circlips, and individual rubber donuts. Adding and subtracting shims, which requires disassembly and reassembly, is time consuming.

***************

2) The MK3 version #06-7116 (no shims).

One of the upgrades to MK3 models was the

Although designed for Mk3 models, it was found that early ISO mountings could be modified to accept this more user-friendly style. The modification required removing 1/4" of metal (6.35mm) off one side of the tube.

***************

3) Retro kit #06-7337. That's what we're installing here. It's for pre MK3's and no modifications are necessary.

The 06-7337 retro kit includes thrust washers made of PTFE (polytetrafluoroethylene), which is a synthetic material known for its non-stick, low-friction, and chemical-resistant properties.

Unlike the early style, the mid-section rubbers are bonded together as one piece.

***************

Prep and Lube

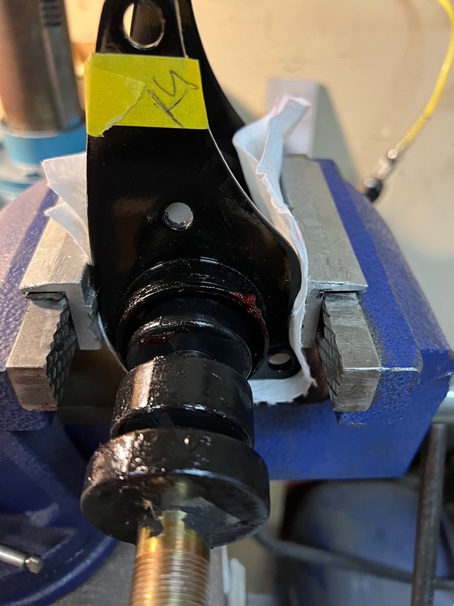

After the front mounting was cleaned, sanded and painted, it was set up in the work bench vice.

Rubber Grease

A lubricant is needed to install the new one-piece center tube. Silicone sprays will get the job done, but may contain solvents which could degrade the rubber.

The recommended lubricant is red rubber grease. Unlike petroleum-based greases, it does not harm rubber. Also good for rebuilding brake calipers.

As featured in the 1958 classic horror film "The Blob".

***************

Front Isolastics Installation

After coating the center-tube rubbers and tube ID with grease, installation requires no more than a firm push by hand.

A piece of wood in between makes it even easier.

Even up both ends, then install washers and thread on left and right caps.

On the front Iso, the adjuster collar is on the right (timing side) and abutment (set-screw) collar on the left (primary side).

After tightening the left-side set screw, the right-side cap threads on, then hand-tightened until no play, and then backed off about 1-1/2 holes. Checking with a feeler gauge, this should yield .006" of clearance.

Rubber gaiters are installed after adjusting free play. Coat inside of gaiters with rubber grease before installing.

With the ISO mounting back on bike, the through-bolt goes in from the timing side. Mounting bolts get torqued to 30 lb/ft.

Re-check clearance with both wheels on the ground.

***************

Rear Isolastics Removal

The factory service manual suggests removing the power unit (engine, transmission, cradle, gearbox) to replace the rear Iso bushings.

There are certainly ways around this. If you're not overhauling the complete motorcycle, here's a way to achieve the needed clearance:

On 1971 and up models, remove the exhaust, head steady, coil bracket, coils, and rear wheel.

Disconnect rear shocks from swing arm.

Disconnect and plug up oil hoses.

A few other things may have to be moved out of the way to get enough access to remove the old parts and fit the new.

Sliding out the long engine mount stud releases the rear Iso components (gaiters, collars, washers, caps, bushes, and shims).

The 06-7117 rear Iso kit is a direct replacement for MK3 models and can be retrofitted to 1968-1974 models.

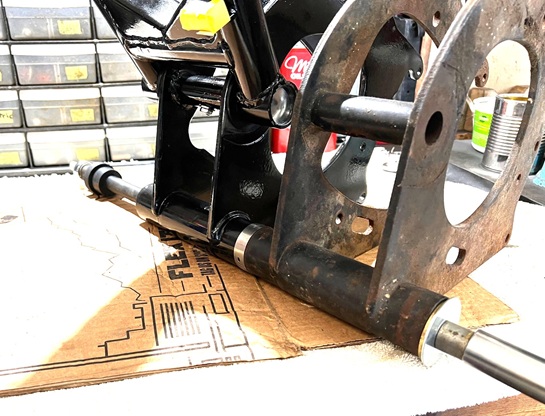

During the restoration of my 1974 Commando, the bike had been stripped down for a complete restoration, including the swingarm and cradle.

Read: Swing Arm Removal

Read: Swing Arm Overhaul

***************

Rear Isolastics Installation

To pull the one-piece center tube through the cross-tube, you'll need a piece of 1-1/2" ID metal pipe, and a long threaded rod with nuts and washers on either end.

I happened to have had a loose cradle from a 1971 Commando, which has the same size and length tube.

A length of 3/8" threaded rod went through the new Iso center-tube and through both cradles, with an automotive hose clamp holding the two cradles together. Large flat washers and nuts were installed on both ends.

Tightening one side with a socket slowly pulled the new Iso assembly through.

On the rear, the adjuster collar is on the left (primary side) and abutment collar (set-screw) is on the right (timing side).

***************

Notes and Misc

If the bike is not apart, front Iso's are much easier to replace than the rears!

Because replacing rear Isolastics is a labor intensive job, consider performing other related services at this time.

***************

Related Articles:

Norton Commando Build - Main Page

Remove Front End

Front Forks Disassembly

Front Forks Overhaul

Swing Arm Removal

Swing Arm Overhaul

Norton Commando Upgrades