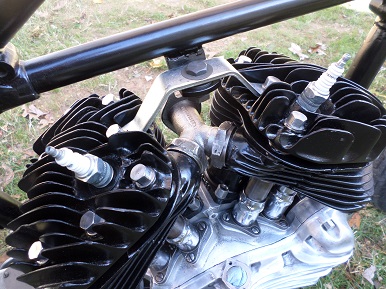

Harley 45 Cylinder Assembly and Installation

Text and Pictures by Mark Trotta

In this segment of the Harley 45 flathead overhaul, we're checking the guides and seats, installing valves, springs and covers, bolting cylinders onto the crankcase, and installing the heads.

Before assembling the cylinder jugs, we need to check that valve guides and seats are Ok for re-use. Here's one way to test for a good seal:

With cylinders removed from the crankcase and with valves and springs still installed, stand them upright on the workbench. Fill the ports with water and let stand overnight. A full port of water the next day means the seal is good.

Valve Guide and Seat Inspection

If guides are worn and out of spec, they should be replaced. A cheaper option is to renew them by knurling.

Related Articles:

How To Remove Valve Guides

How To Install Valve Guides

How To Measure Valve Guide Wear

******************

Valve Lapping

If the guides and seats are in good condition, the lapping process should take less than a minute for each valve. It actually takes longer to clean, prepare, and round up the supplies than to actually lap the valves!

You'll need a tube of valve-grinding compound and a valve lapping tool, which is basically a wooden dowel with a suction-cup on the end.

Read: How To Lap Valves

The purpose of a valve job is to have the valve and seat make an air-tight fit.

The purpose of lapping is to verify that the grinding was done correctly.

*****************

Parts Interchange

Intake valves and guides, exhaust valves and guides, retainers, keepers, and covers are all same for 1930 through 1973 Harley 45 flatheads.

Valve head diameter is 1.625" on both intake and exhaust, but they are not interchangeable. Exhaust valves are different in that they are heat-treated.

Shop: Valve Spring Kit For Harley WL/G 1941-1973

Cylinder Prep

Prior to assembling, the outside of the cylinders were cleaned and scuffed with a Scotchbrite pad, then painted semi-gloss engine black.

Valve Installation

Before slipping valve stems into the guides, lubricate with a little engine oil.

Once the valves are in the guides, install valve guide oil seals, lower valve spring covers, valve cover seals, upper cover, springs, collars, then install valve keys.

Here, I'm using an automotive valve spring compressor. It was a little awkward, but it worked!

Installing Cylinders on Crankcase

Lubricate cylinder walls, pistons, pins, and rod upper bushings generously with engine oil. Pour some oil onto the rod lower ends as well.

If you haven't done so yet, space ring gaps equal distances apart, and leave no gap facing exhaust port.

Turn engine until crank pin is at bottom center.

Do not use sealant on base gaskets. Install them dry.

Install rear cylinder first. Carefully work assembled cylinder over piston and rings. As the cylinder seats, turn engine so tappets are at their lowest position.

Thread on base nuts, but do not tighten yet. First, install and tighten the intake manifold bolts, then shift and align both cylinders, then tighten base nuts.

After the front cylinder is installed, both front and rear may need to be shifted slightly to fit the intake manifold.

*****************

Engine Gaskets

James Gasket offers a complete gasket set for 1936 through 1973 Harley 45 Flatheads. It replaces H-D 17026-40 gasket kit.

James Gasket products are made in USA, just like your Harley was.

Install Heads

There are eight bolts per head. The two longer bolts go through the frame bracket.

Tighten head bolts evenly. After snugging, turn each one 1/4 turn until all are securely tightened.

The Harley service manual does not provide torque specs, so use your best judgment.

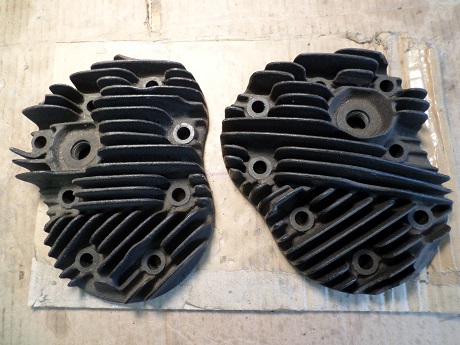

Cast Iron vs Aluminum Heads

Most Harley flathead cylinder heads are cast-iron. If yours are cracked or have broken fins, finding good used replacements is easy.

There are at least three different cast-iron heads, and there's several different compression ratios:

1) 1937 to 1950 with 3/8" stud holes.

2) 1951/1952 WL and 1951 to 1955 Servi-cars with 7/16" bolt holes.

3) 1956 to 1973 have 14mm spark plugs holes instead of 18mm and have 7/16" bolt holes and larger fins.

Compression Ratio

There is usually a number stamp on the head to indicate compression ratio.

Heads marked 5.0 are low compression (5.0:1). If it reads 6.0 it is considered high compression (6.0:1).

Here in the 21st century, it's hard to believe that 6.0:1 was once considered high compression, but the reader must remember that high-octane fuel and high compression engines came after (and were actually by-products) of World-War-Two.

Aluminum Heads

A set of aluminium heads not only bump up compression, they dissipate heat better and are lighter than cast-iron heads.

Finding a set of good original Harley 45 aluminum heads is not easy. V-Twin Manufacturing now offers aftermarket replacements.

NOTE: Aluminum cylinder heads require head bolt washers.

All WLA military bikes were factory-equipped with aluminum heads.

****************

Replacement Cylinders

V-Twin Mfg. catalogs front and rear cylinders as a set (11-1099), but the rear cylinder is not always available.

As of this writing, Harley 45 front cylinders are still available.

*****************

Related Articles: