850 Commando Bottom End Assembly

Article by Mark Trotta

Continuing with the 1974 Norton Commando engine overhaul:

Like all classic British Twins, Commando engines have left and right engine cases. To avoid confusion, they are referred to as drive-side and timing-side.

Main Bearings

Standard issue on all 850's were 'Superblend' bearings, part # NJ306E and manufactured by F.A.G.

Factory installed Superblends had a brass cage with a double-lipped outer race that retains the roller cage.

The inner races are single-lipped and are attached to the left and right crankshaft.

To remove main bearings, heat up the case, turn it upside down, and with a few light taps the bearing should fall out.

On this 1974 Roadster, the bottom end was clean and tight, and the main bearings did not need replacing.

****************

Crankshaft Assembly

With all needed parts rounded up and everything neat and clean, it's time to begin engine assembly.

Read: Sludge Trap Cleaning and Crankshaft Reassembly

Read: Crankshaft Journal Polishing By Hand

****************

Connecting Rods and Bearings

Original Commando connecting rods were manufactured from high quality aluminium. The bottom caps are cast iron.

Connecting Rod Polishing

Any rough edge on the rod (like a nick) is considered a 'stress riser' and should be removed as a safeguard against possible cracking.

One of the rods was found to have a few small nicks in it.

After sanding out the nicks with Emory cloth, they were wet-sanded with 240 grit, followed by 400 grit.

Any sanding should be done lengthways, up and down the beam and not across it. You really don't want to remove any metal, just make it smooth.

The rod caps are steel and do not get polished.

Final polishing was done on a buffing machine with a 30-ply buffing wheel.

The bottom end of your motor relies on oil for lubrication and reducing friction.

By holding rod up to light, you can check that oil holes are clean and clear.

Replace Con Rod Bolts?

On high mileage bikes, or if it looks like the bottom end has been gotten into before, replacing the bolts may be prudent.

But, there's potential trouble when knocking old bolts out--and getting correct quality replacements--and having them go in correctly.

Quoting the factory workshop manual: ...it is unnecessary to renew the connecting rod bolts though new nuts should always be used."

So, the big-end bolts were left alone, with new nuts installed.

Con Rod Bearing Inserts

Norton Twin connecting rods have bearing shell inserts. There are two different ones--the upper has an oil hole which goes into the connecting rod. It has a tab which should mate with the rod.

The lower bearing shell has no hole, and goes into the rod cap. It also has a tab which should mate with the cap.

Con-rod nuts torque to 25 lbs/ft. Correct socket size is 1/4 Whitworth.

When installing, the oil holes on rods face outward.

****************

Assembly Lube

During initial engine fire-up, assembly lube protects internal parts for those crucial 10 seconds before the engine can establish oil pressure.

For those who don't have a favorite assembly lube, read this article.

****************

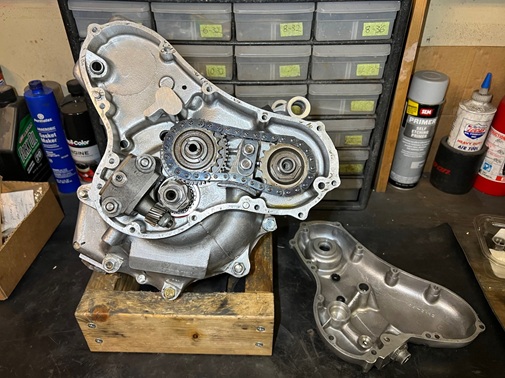

Install Crank Assembly In Case

A simple work box was made of 2x4 wood pieces, and it helped make engine assembly a little easier.

Setting the drive-side case on the wooden box, the crank assembly was gently lowered into position, making sure both con rods clear the spigot.

CAUTION: The alloy rods can be easily damaged by knocking into the sharp crankcase mouth. Protect them with whatever you have handy--rubber hose, foam, bubble wrap, etc.

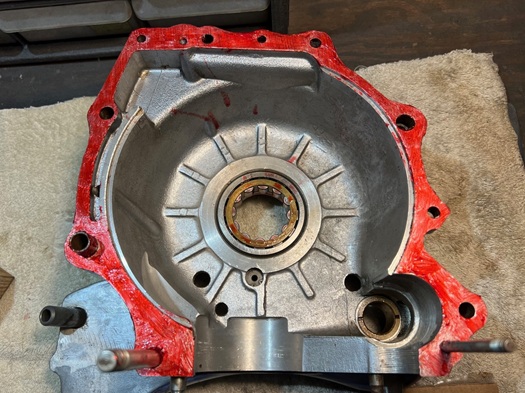

Gasket Sealant

Crankcase halves receiving a coat of anaerobic gasket maker.

Permatex 51813 sealant works very well with split engine cases.

Allow sealant 3-5 minutes to get tacky.

Camshaft Install

Camshaft thrust washer is installed with taper to the tacho worm drive.

NOTE: On earlier Commando engines (between 200000 and 300000), there is an additional flat thrust washer with spring on the other end of the camshaft.

The timing-side case was lined up and carefully set down over drive-side case. A little case wiggling was needed.

After checking that the camshaft and crank assembly were rotating smoothly, crankcase fasteners were installed and tightened.

Additional bolts were temporarily installed in front and rear mount bosses.

****************

Install Pinion Gear

First, the round sealing washer goes over the timing-side shaft, then the triangle-shaped washer (crankshaft pinion back plate) goes on.

Next, the woodruff key is installed. The flat end of the key faces engine.

NOTE: Camshaft and crankshaft keys are the same.

With appropriate-sized socket and hammer, tap on pinion gear just until triangle washer no longer spins.

****************

Left Hand Nut

After pinion gear is on, LEFT-HAND oil pump worm gear threads on.

Oil pump worm gear torque is 20 lb/ft.

Do Torque Wrenches Work Backwards?

There are specialty "dual-way" torque wrenches which are designed to work both ways, but generally, torque wrenches cannot be reversed.

To torque a left-handed nut or bolt, here's a simple hack:

With a standard ratchet, tighten the nut/bolt to the left a little bit past specified torque. Then use a torque wrench set just below the desired torque threshold to check it.

NOTE: To prevent the crank assembly from spinning while tightening, insert a suitably-sized bar into connecting rods.

****************

Oil pump studs were torqued to 95 Inch/Pounds, which is about eight foot/pounds.

Oil pump stud nuts were torqued to 140 Inch/Pounds, which is about 12 foot/pounds.

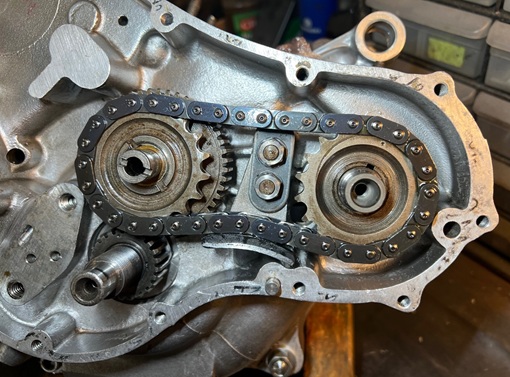

Timing chain, intermediate gear, and cam sprocket are installed as an assembly.

Read: 850 Commando Timing Chain Installation

****************

Sump Filter and Drain Plug

A special spanner wrench is available to remove and install the crankcase sump filter, but a 38mm socket works just as well.

By removing the circlip, the gauze inside the sump filter may be cleaned or replaced.

The oil drain plug removes/installs with a 9/16" wrench or socket.

****************

Related Articles: