Solder or Crimp Wires

Article by Mark Trotta

Electrical wire can be soldered or crimped onto terminal ends. So which way is better?

Spoiler Alert - In 90% of all cases, crimping is the better method in a wiring harness.

************************

First, let's start off by acknowledging that both crimping and soldering can be done incorrectly. And when either are done poorly, both are bad!

So, a good solder connection is better than a bad crimp, and

A good crimp is better than a bad solder connection.

************************

When To Solder Wires

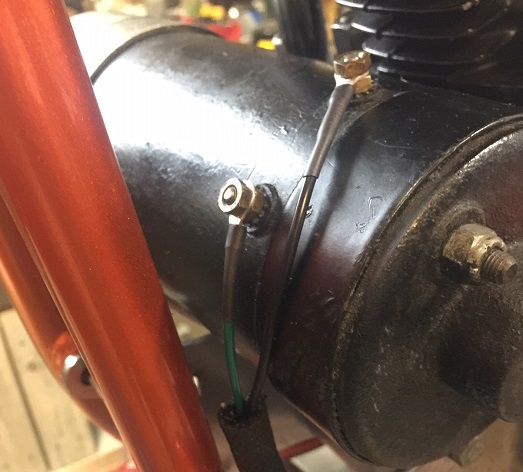

Period Correct - Plastic-covered crimps don't look right on a vintage motorcycle.

After a little research, I learned that the automotive and motorcycle industry did not start crimping terminals until the 1960's. But this was not done because it was better, it was done because it was cheaper and faster.

Do-overs - I have soldered headlight and taillight circuits after someone previously used improper crimp connections.

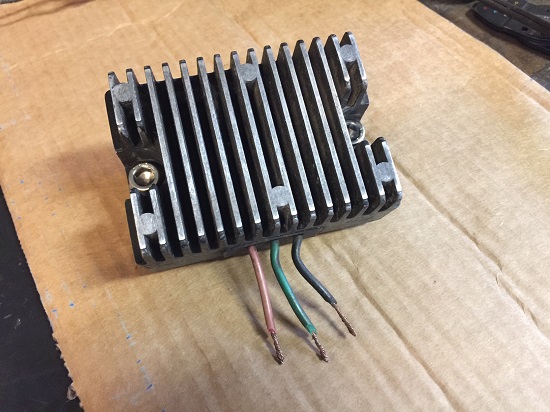

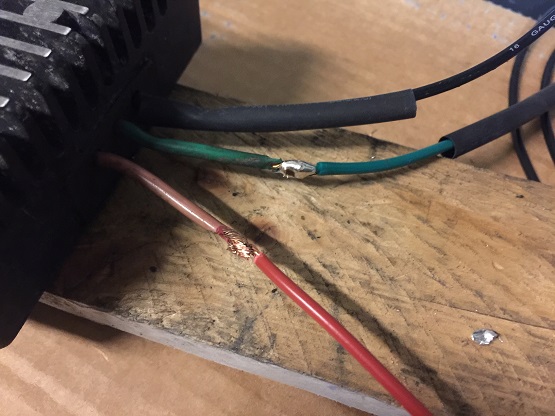

Visual - This electronic voltage regulator had it's wires cut way too short. As you can see, there wasn't much left.

In this scenario, soldering was chosen to rejoin the wires.

The end result looks better than if using bulky butt connectors.

************************

The Vibration Factor

Crimping is more resistant to vibration and movement that may cause solder to crack loose or potentially snap. Wire-to-wire connections crimped correctly will not vibrate apart.

************************

Crimping wires correctly requires an inexpensive tool.

Shop: Crimping Pliers

************************

Solderless Wire Connectors

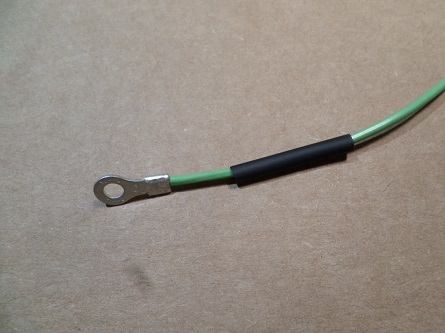

When I install crimp connectors, I remove the plastic sheath it comes with and use an inch or so of shrink tubing. IMHO, it looks better.

After crimping the terminal, check tightness by pulling on it with your fingers.

Heat the shrink tubing with a lighter. The wire terminal connections are now sealed and protected.

Connecting Wires With Butt Connectors

There is little skill required to connect two wires with a butt connector. Because of that, or in spite of it, they are often seen as an amateurish attempt to repair wiring.

Although they have a reputation for being misused and over-used, butt connectors make a fast and easy repair when installed correctly.

************************

Crimp Connectors

Wire crimp connectors do not require soldering and are an easy method for repairing broken wires.

Don’t forget to add heat-shrink tubing BEFORE you make the join!

Heat Shrink Connectors

An alternative to removing the hard plastic sheath of the terminal and adding shrink tubing is to buy heat-shrink terminals.

After crimping the terminals on with crimping pliers, apply heat with a lighter while rotating the connector. The heat shrink tubing reduces in size and adheres to the wire.

************************

Related Articles: